Add to Cart

Plastic Waste HDPE Film PP Woven Bag Shopping Bag Washing Drying Recycling Line

PP/PE washing line basic instructions

This set is developed through the introduction, digestion and absorption of advanced concepts and technologies at home and abroad, combined with the needs of today's development and the recycling and utilization of waste plastics. It can meet the environmental protection requirements for recycling of waste plastics at home and abroad. Handle soft floating plastics such as discarded braids and films!

PP/PE washing line product features

This set is a new generation of high-efficiency and water-saving equipment newly developed by our company. The machine features: beautiful appearance, low energy consumption, high output, practical and reliable. The new rinsing device can be used with the washing, greatly improving the production efficiency, and the cleanness of the washing material is pure. The production line is very popular and concerned by users in the field of green environmental protection. It is also one of the equipment actively recommended by the national environmental protection department. It will bring huge economic benefits to users in environmental protection and efficient use of energy.

PP/PE washing line parameter specifications

The output of this set of equipment: 300-1000kg/h (can be customized according to customer requirements)

PP/PE washing line application range

This set mainly deals with PP/PE waste plastic film, PP/PE plastic garbage mixture, waste PP woven bag (cement bag, space bag, snake skin bag), PP/PE plastic bag, household garbage plastic, PE plastic garbage bag, Waste agricultural film mulch film, PVC agricultural film.

PP/PE washing line works

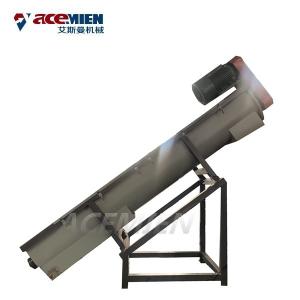

This set of equipment mainly consists of: conveyor belt, crusher (pulverizer), friction cleaning machine, sedimentation rinsing tank, chain material excavator, plastic squeeze dry dewatering machine, control cabinet and so on. The waste plastics are sorted (sorted), crushed (with water crushing), friction cleaning, rinsing, squeezing and dewatering, etc., and the entire production line starts from waste to finished product, and the waste plastic products are cleaned very efficiently. Dirty agricultural film, waste packaging materials. Easy to operate, high efficiency, environmental protection and energy saving.

| High speed friction washer | Technical data |

|

1.Motor power:30kw 2.Rotor diameter:580mm 3.Rotating speed:1200rpm 4.Effective length:2000mm 5.Vane thickness:10mm 6.Screen thickness:2mm 7.Material contact parts are made by stainless steel 304 |