Add to Cart

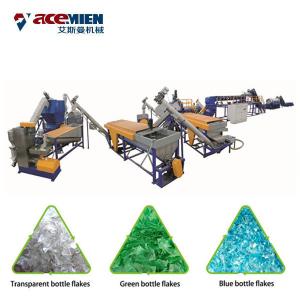

Waste plastic bottle woven bag film washing recycling Machinery 1000kg/hour

environmental project & high profit.

1. It can protect our enviroment from attact of white trash(the waste plastic bags, films etc.

2. high profilt, raw material - waste PE/PP films & bags are very cheaper, even no need pay can get, after washing recyclied it become high value products.

BenK supply high efficency enginner team for help client installtion machine & training their works how operation our machine.

Basic specification of plastic pet bottle recycling machine/plastic recycling plant/pet bottle washing line

| Product capacity | 300kg/h | 500kg/h | 1000kg/h | 1500kg/h |

| Workshop(L*W*H) | 40m*7.5m*6m | 42m*10m*6m | 70m*12m*6m | 75m*15m*6m |

| Needed worker | 3-4 persons | 5-6persons | 7-8persons | 10-12persons |

| Water supply | 2-3ton/h | 3-5ton/h | 7-10ton/h | 10-15ton/h |

| | Moisture: max 3% | |||

common configuration of pet bottle plastic recycling machine/plastic washing machine/waste plastic bottle recycling plant

| No. | Equipment Name | Quantity | Comments |

| 1 | Belt conveyor | 1 set | |

| 2 | Bag opener | 1 set | Optional |

| 3 | Belt conveyor | 1 set | |

| 4 | Trommel | 1 set | Optional |

| 5 | Belt conveyor | 1 set | |

| 6 | Manual sorting conveyor | 1 set | Optional |

| 7 | Belt conveyor | 1 set | |

| 8 | Crusher | 1-2 sets | |

| 9 | Screw conveyor | 1 set | |

| 10 | Washing tank | 1 set | |

| 11 | Screw conveyor | 1 set | |

| 12 | Cooking boiler or Horizontal Hot washer | 1-2 sets | |

| 13 | Screw conveyor | 1 set | |

| 14 | High-speed washer | 1 set | |

| 15 | Washing tank | 1 set | |

| 16 | Screw conveyor | 1 set | |

| 17 | Horizontal Dewatering Machine | 1 set | |

| 18 | Cyclone separator | 1 set | |

| 19 | Drying system | 1 set | |

| 20 | Label separator | 1-2 sets | We can equipped with two label separators in the whole line, one at the beginning, another at the end |

| 21 | Final product silo | 1 set | |

| 22 | Control System | 1 set |